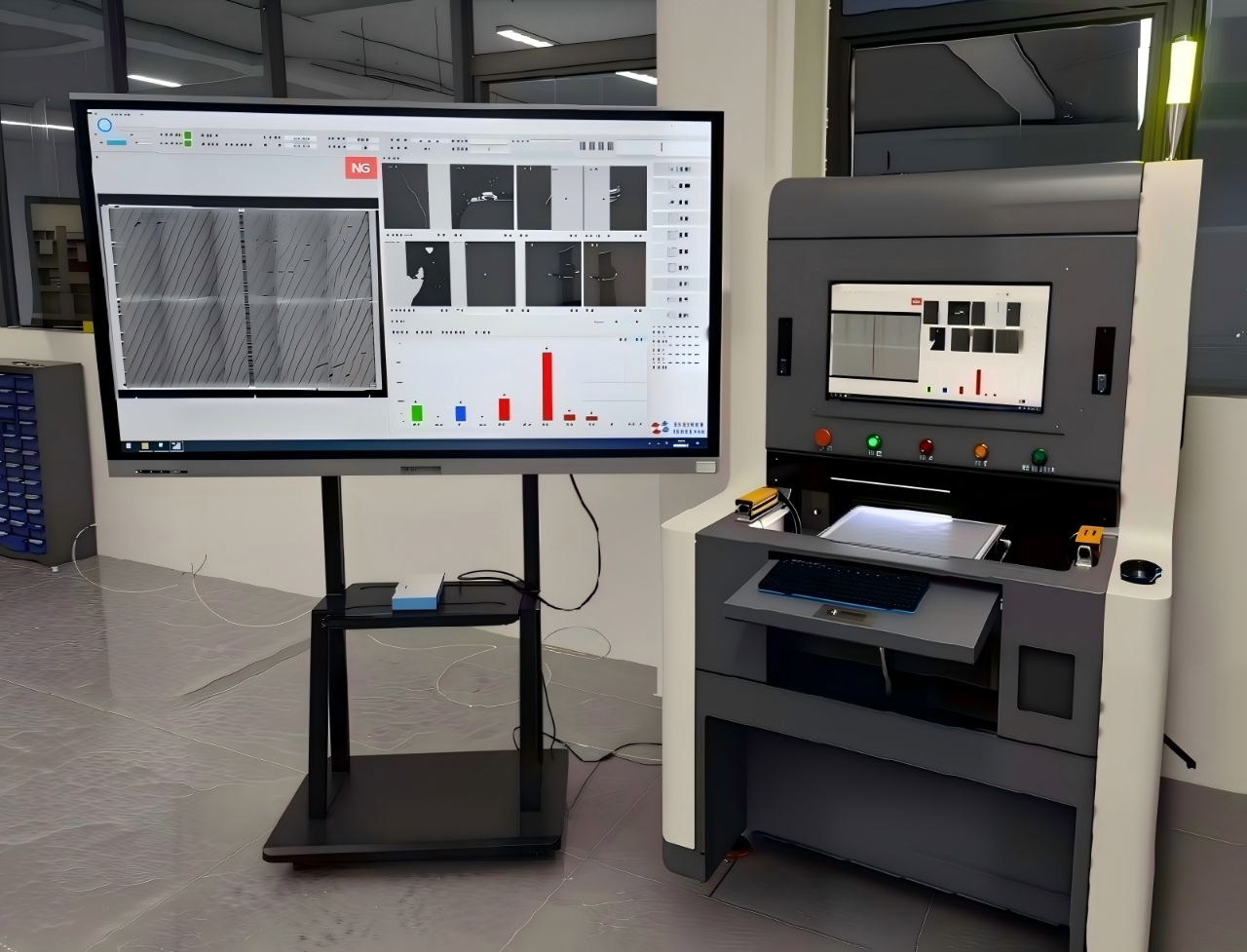

In the manufacturing process of MLCCs (Multi-Layer Ceramic Capacitors), the integrity of electrode patterns directly determines the electrical performance and reliability of the products. Film appearance defects during the electrode printing stage after tape casting are often a key factor affecting production yield. How to achieve automated inspection with high precision, high speed and traceability? Hitech Precision Industry proudly launches the Offline Ceramic Printed Appearance Visual Inspection Machine, driven by AI + optical technology, setting a new standard for MLCC inspection!

01 Product Overview

1.Specially Designed for the Front-End Process of MLCC

Serving as the visual core of the system, the camera must deliver high definition and high compatibility, ensuring the capture of micron-level defects on printed surfaces.

To meet the multi-specification adaptation requirements for printed films with different patterns, the operation interface is designed with the priorities of reducing complexity and enhancing intuitiveness. Visualized parameters make the adaptation status clear at a glance, ensuring that operators can quickly switch the inspection settings for films with different patterns and models without professional expertise.

2. Defect Types Covered

Protrusion、Depression、White spot、Black spot、Serrated edge、White patch、Burr、Smear、Incomplete printing、Deformation.

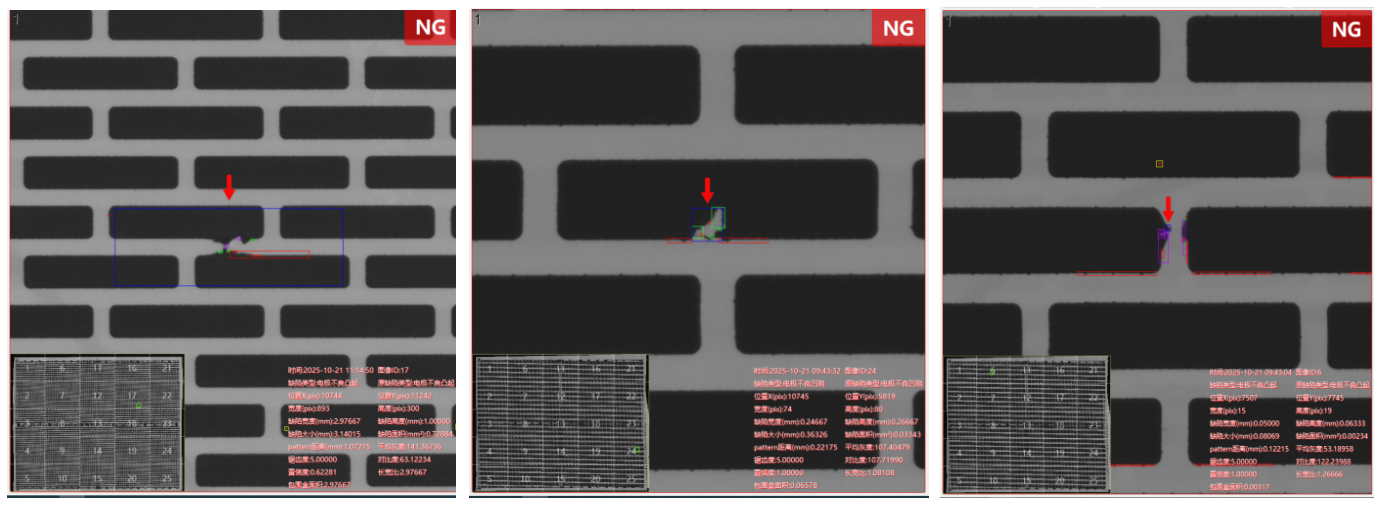

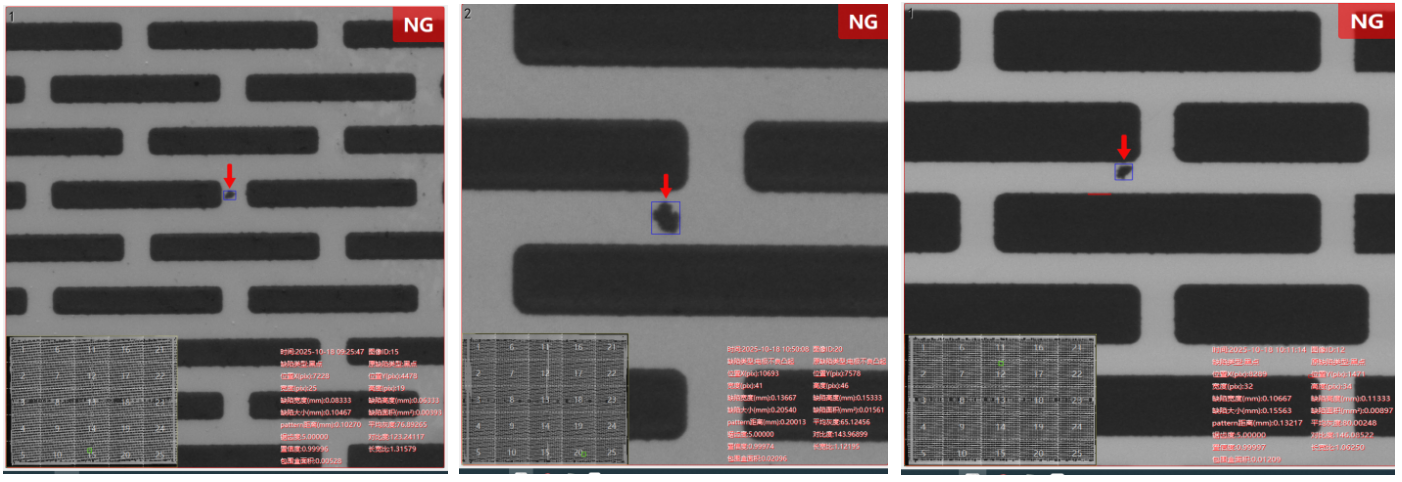

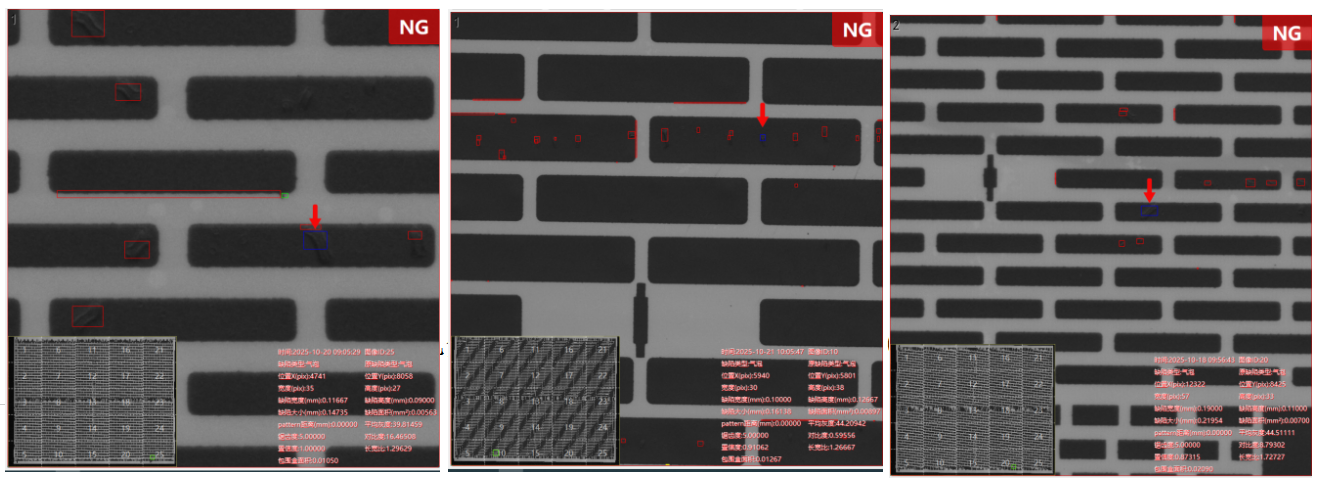

Protrusion、Depression

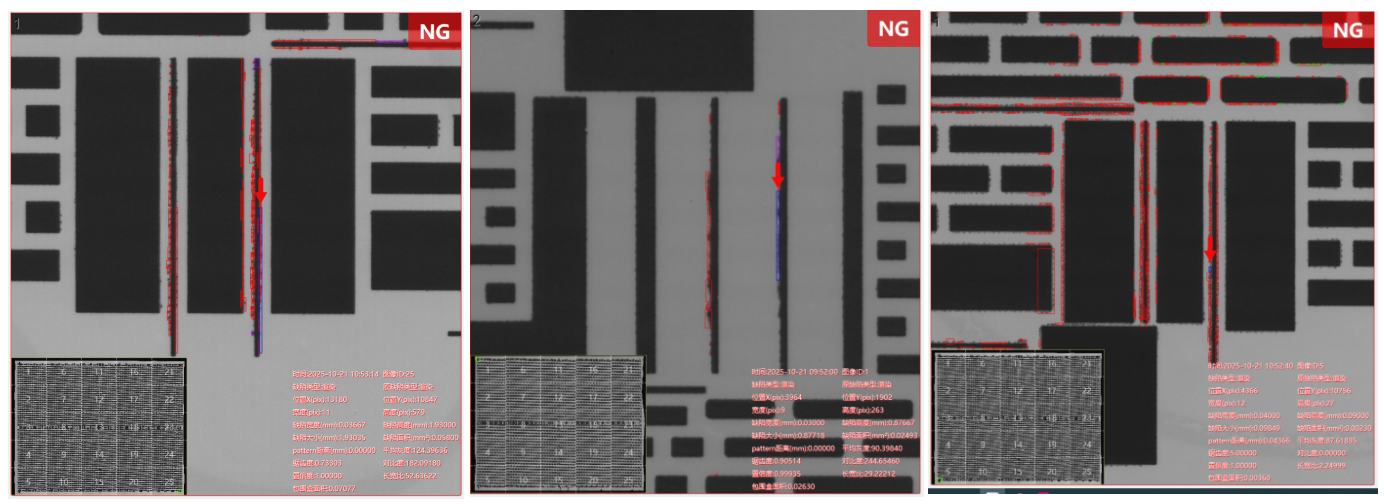

Burr、Smear、Serrated Edge

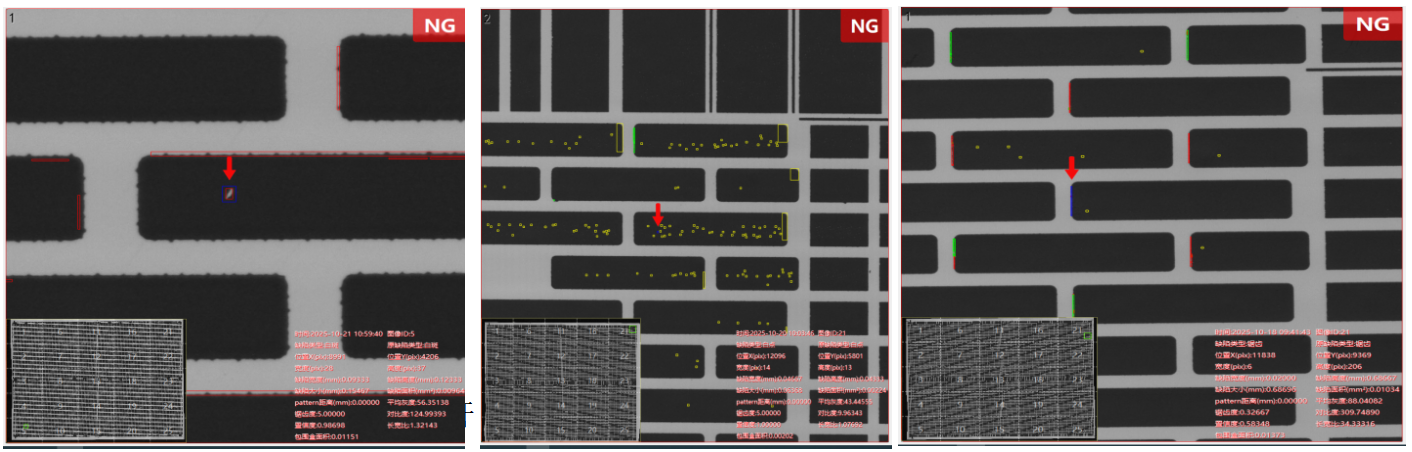

White Spot、White Patch

Black Spot

Bubble

02 Core Advantages

-

Ultra‑High Resolution Imaging System:The camera features a resolution of 16384, with a single‑pixel accuracy of 0.004 mm (4 μm). It can clearly capture micron‑level defects, ensuring zero missed detection.

-

Efficient and Stable Inspection Performance:The inspection speed is ≤60 seconds per piece (standard model). It supports flexible switching between offline and standalone modes, and is compatible with various product models to meet diverse production requirements.

- AI Intelligent Judgment + Positioning and Traceability:The system adopts dual algorithms: traditional image processing and AI deep learning. It can automatically classify defect types and mark their coordinate positions. The inspection data can be exported to the MES system, realizing full‑process quality traceability.