Empowering Full Process, Smart Manufacturing for Future | HITELSEIKO Creates MLCC Intelligent Equipment Integrated Solution

![]() 2025-08-13

2025-08-13

With the rapid development of high-end electronic products such as 5G communications, new energy vehicles, and AI terminals, MLCC (Multi-Layer Ceramic Capacitors), as the “cornerstone component” of electronic systems, is accelerating towards miniaturization, high capacitance, and high reliability. Manufacturing precision has entered a new stage of nano-level control, full-process automation, and full-process traceability, posing unprecedented challenges to the stability, consistency, and intelligence level of production equipment

Facing this trend, HITELSEIKO, relying on core technologies of AI Machine Vision + Industrial IoT, deeply lays out the full MLCC industry process. We build intelligent equipment and inspection systems covering 14 key processes, providing integrated full-process solutions from raw material processing to finished product packaging, helping customers achieve efficient, stable, and intelligent large-scale production.

HITELSEIKO Key Equipment Full Coverage

Equipment + Process + Inspection Three-in-One

Front-End Process: Precision Foundation

HS-TM Series Casting Film Inspection Machine: Real-time online inspection, defect accuracy 0.02mm/pixel, pinhole inspection accuracy 10μm.

SUS Steel Plate Surface Defect Inspection Machine: AI algorithms identify scratches, pits, and contamination to ensure substrate quality.

Bar Board Appearance Visual Inspection Machine: High-precision vision automatically determines and marks defect positions.

Online Printed Film Inspection Machine: Real-time online inspection, inspection speed ≤12 seconds, single pixel accuracy 0.008mm.

Mid-End Process: Smart Manufacturing Empowerment

Product Alignment Machine: High-speed and precise alignment ensures uniform binder burnout and firing, improving sintering yield.

Grinding & Chamfering Automatic Dosing Machine: Realizes fully automatic weighing and feeding of multiple auxiliaries, eliminating human deviation.

Multi-Form Series Screening Machines: Supports automatic sorting of multi-size products, quickly rejecting defective products, saving time and labor, and improving production line cycle time.

Back-End Process: Quality Closed Loop

Ceramic Capacitor Weighing & Visual Counting Machine: Perfect combination of optics and vision, overcoming the weighing and counting problem of micro-capacitors.

Automatic Packaging Line: Automatic label verification, appearance self-check, rapid product output.

Whole Line Process: Full Domain Intelligent Control

Hi-Cloud Platform: AI IoT, central integrated control, intelligent analysis, problem prediction.

In addition to the above products, HITELSEIKO also provides other series of intelligent equipment, covering all links of the MLCC process to meet diverse production line needs.

Why Choose HITELSEIKO?

Foresight to foresee future leading scenarios, forming advanced concepts. Standing at the commanding height to form rapid advanced technologies and organizational capabilities for advanced processes. Creating leading products. Combined with advanced product planning and operational capabilities, guiding engineering to form standardized and modular design capabilities. Using cutting-edge process equipment to realize streamlined production and efficient, simplified delivery.

A domestic manufacturer that realizes independent development and integration of full-process equipment including casting, printing, stacking, isostatic pressing, cutting, sintering, grinding, termination, electroplating, and taping, providing truly “One-Stop” delivery.

Breaking the long-term monopoly of Japanese and Korean equipment, successfully introduced into multiple top domestic MLCC manufacturers, running stably in batches, helping the industry chain become autonomous and controllable.

Under the general trend of intelligent manufacturing, HITELSEIKO’s MLCC production line is no longer just “equipment stacking,” but a one-stop intelligent solution deeply integrating process, equipment, data, and quality. With the core concept of “Full Process Empowerment,” HITELSEIKO continuously promotes the localization, standardization, and intelligent process of MLCC equipment.

查看详情 >

Inauguration Ceremony for GSTECH’s “Intelligent Inspection Equipment and Intelligent Production Line” Project Grandly Held in Zhanjiang

![]() 2024-12-31

2024-12-31

On December 31, 2024, the unveiling ceremony for GSTECH’s “Intelligent Inspection Equipment and Intelligent Production Line” project was grandly held at the “Zhanjiang City Development Intelligent Manufacturing Industrial Park” within the Guangzhan Industrial Park. Relevant leaders from the Zhanjiang Municipal Bureau of Industry and Information Technology, the Municipal Investment Promotion Bureau, the Municipal City Development Group Co., Ltd., and the Municipal Industrial Investment and Development Co., Ltd. attended the ceremony.

Unveiling Ceremony

The “Intelligent Inspection Equipment and Intelligent Production Line” project of Zhanjiang Hitelseiko Intelligent Technology Co., Ltd. involves a total investment of 140 million RMB. The first phase is expected to commence production by the end of June 2025, with a projected annual revenue of 60 million RMB in the same year. The establishment of this project is expected to introduce upstream and downstream enterprise resources, thereby driving the development of the entire intelligent inspection and machine vision industry chain in Zhanjiang and forming an industrial ecosystem cluster. Furthermore, following its implementation, the project will activate and release new industrial momentum and space within the local park, injecting new vitality into the local economy and accelerating the gathering of “Specialized, Refined, Differential, and Innovative” (SRDI) industries in the park.

Pei Yanming, General Manager of GSTECH, stated that the company will establish its pan-semiconductor intelligent inspection equipment and intelligent production lines in Zhanjiang. The company is committed to reshaping the intelligent production and inspection of the pan-semiconductor industry, such as the MLCC sector and ceramic substrates. Utilizing Zhanjiang’s unique geographical location, the city will serve as a strategic bridgehead radiating to the Southeast Asian market. With Shenzhen as its R&D center and Zhanjiang as its production layout, GSTECH aims to build a core module and equipment production base, as well as a product contract manufacturing base, serving strategic emerging markets such as Vietnam, Thailand, and Malaysia. With the slogan “Forging Ahead, GSTECH Blooming in Zhanjiang,” he expressed his determination regarding the company’s development in Zhanjiang.

General Manager Pei Yanming Delivering a Speech

At the unveiling ceremony, Xu Jian, Secretary of the Party Committee and Director of the Management Committee of Fenyong High-tech Zone, as well as Director of the Guangzhan Park Management Committee, stated that the commencement of the “Underwater Cleaning Robot Manufacturing Center” and the “Intelligent Inspection Equipment and Intelligent Production Line” projects is a strong testament to the collaboration between the park management committee and the enterprises. It is the result of actively integrating resources such as fund follow-on investments and award/subsidy policies to fully promote project entry. The successful introduction of these two projects is significant for the further development of “New Quality Productive Forces” in the park. He requested relevant departments to provide proactive services, actively coordinate to resolve difficulties during project construction, and ensure that the project progress is smooth and quality is guaranteed, achieving early completion, early production, and early results.

Following the unveiling ceremony, GSTECH General Manager Pei Yanming accompanied the attending leaders on a tour of the company’s office and production facilities located in the “Zhanjiang City Development Intelligent Manufacturing Industrial Park.” He provided a detailed introduction to the company’s renovation plans and business implementation strategies.

Shenzhen Hitelseiko Technology Co., Ltd. is an intelligent equipment service provider integrating R&D, production, sales, and service, with “Machine Vision + Electrical Performance Testing” as its core. The company focuses long-term on fields such as precision ceramics, semiconductors, and new energy, deeply cultivating solutions including AI defect inspection equipment, electrical performance testing equipment, and high-precision alignment equipment.

查看详情 >

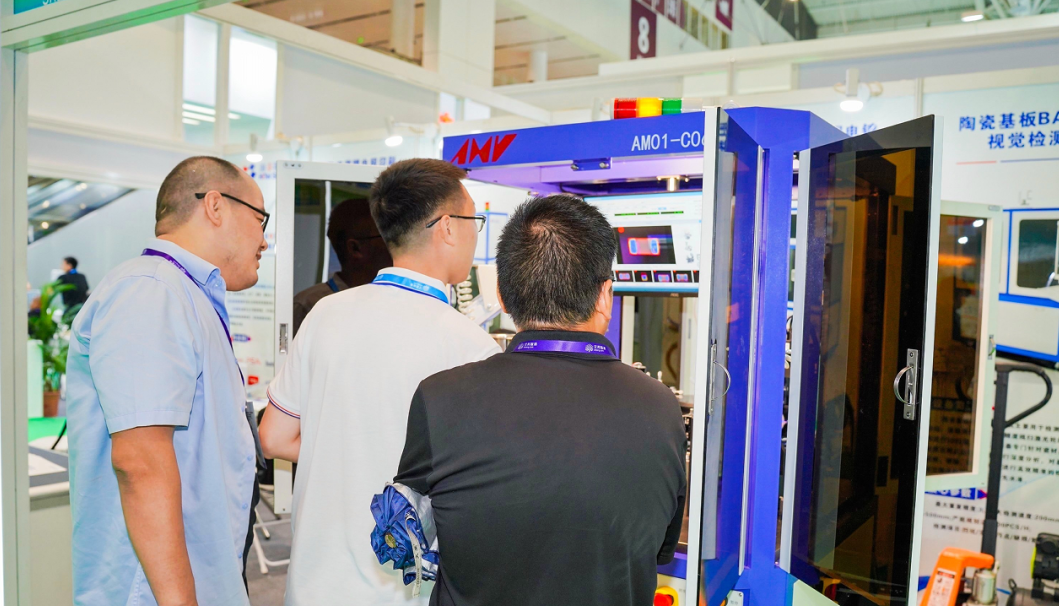

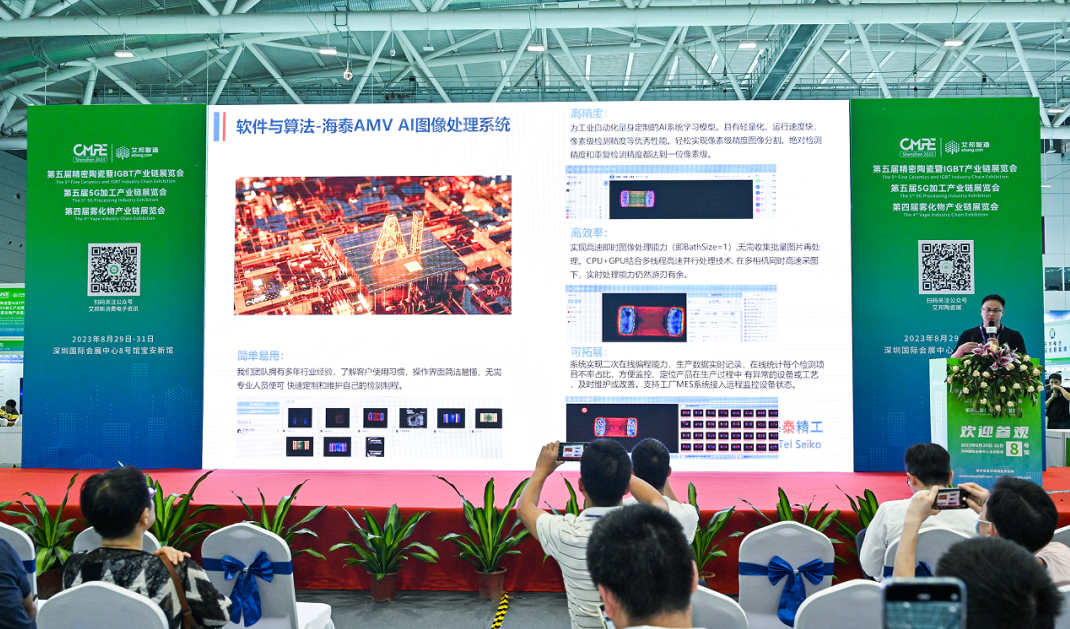

Exhibition Review | Haitai Precision Technology Shines at the 5th Shenzhen Precision Ceramics and IGBT Industry Chain Exhibition

![]() 2023-08-31

2023-08-31

The 5th Precision Ceramics and IGBT Industry Chain Exhibition came to a successful conclusion at Hall 8 of Shenzhen World Exhibition & Convention Center. As a testing equipment company focusing on AI machine vision and electrical performance as its core businesses, Shenzhen Haitai Precision Technology Co., Ltd. garnered extensive attention.

At the forum hosted by the industry, Pei Yanming, General Manager of Haitai Precision Technology, shared his insights regarding the company’s testing cases in the precision ceramics sector and the implementation of AI visual inspection.

At present, Haitai’s six-sided visual inspection machine has also reached the industry-leading level. For the MLCC inspection equipment, it adopts the industry-leading high-definition image processing technology for defect detection, and the maximum speed can still reach 13,000 pcs/min.

查看详情 >

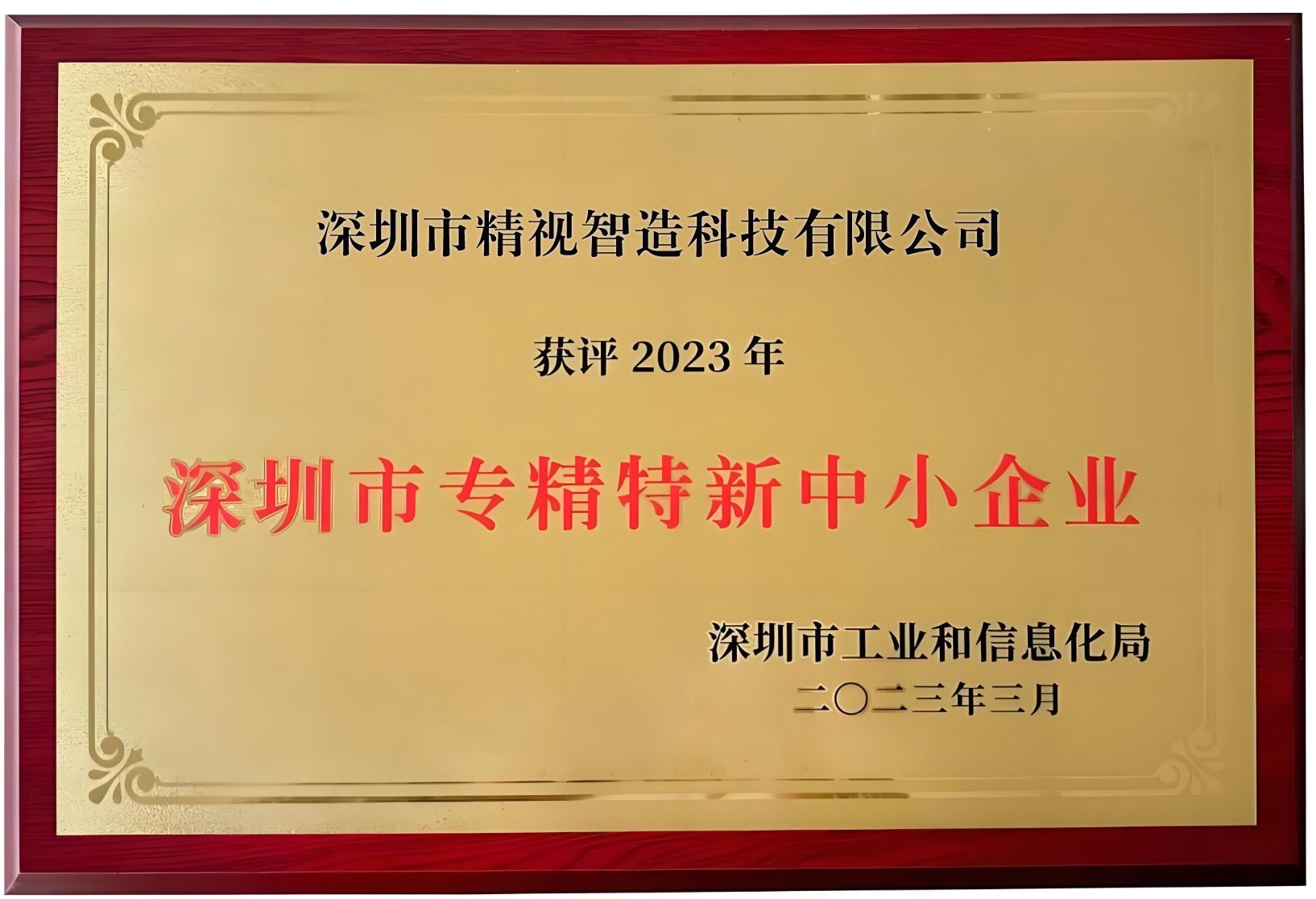

Congratulations to Jingshi Intelligent Manufacturing (a wholly-owned subsidiary of Haitai) on being selected as a Shenzhen Specialized, Refined, Peculiar and Innovative SME

![]() 2023-03-15

2023-03-15

On March 15, 2023, the Shenzhen Municipal Bureau of Small and Medium Enterprises Services announced the list of Shenzhen Specialized, Refined, Peculiar and Innovative Small and Medium-sized Enterprises for the year 2022. Following expert review and comprehensive evaluation, Jingshi Intelligent Manufacturing stood out among over 2.5 million small, medium and micro enterprises in Shenzhen and was successfully certified as a Shenzhen “Specialized, Refined, Peculiar and Innovative” Small and Medium-sized Enterprise.

![]()

“Specialized, Refined, Peculiar and Innovative” (SRPI) is an abbreviation for specialization, refinement, distinctive features and innovation. The number of SRPI small and medium-sized enterprises (SMEs) reflects, to a certain extent, the concentration of “elite players” among local SMEs. A large number of such elite players indicates a vibrant environment for innovation and entrepreneurship, a strong contingent of vital forces driving high-quality economic development, and also demonstrates the core competitiveness and future potential of the local industrial chain.

查看详情 >